Products & Services

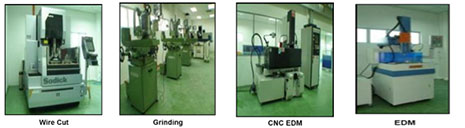

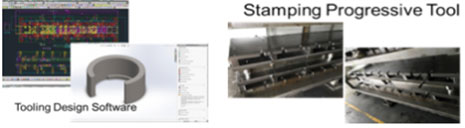

Tooling, fixture design & fabrication

|

|

StampingVarious Material Application

Stamping Material Thickness Application: 0.2~1.0 mm (Depend on material type) |

|

Surface Treatment – Auto Passivation

|

|

AssemblyCustomized Assembly Line and machineries design. |

|

Washing machineMultiple Ultrasonic frequency DI water washing (40KHz~270KHz)

|

|

Form In Place Gasket Plotting

|

|

Die Cut ProcessAdhesive die cut capability base on customer requirement. |

|

Quality AssuranceEquipment for dimensional & functionality assurance in various stages of processing

|

|

Our Product |

|